| PART NO. | Nominal(D) | Effective Lenght | Length(L) | WEIGHT | |

| INCH | MM | INCH | INCH | KG/PCS | |

| B187-100 | 3/16 | 5 | 1 | 1.260 | 0.039 |

| B187-150 | 1-1/2 | 1.760 | 0.042 | ||

| B187-200 | 2 | 2.260 | 0.044 | ||

| B187-300 | 3 | 3.260 | 0.048 | ||

| B250-050 | 1/4 | 6 | 1/2 | 0.790 | 0.053 |

| B250-100 | 1 | 1.290 | 0.057 | ||

| B250-150 | 1-1/2 | 1.790 | 0.060 | ||

| B250-200 | 2 | 2.290 | 0.064 | ||

| B250-250 | 2-1/2 | 2.790 | 0.067 | ||

| B250-300 | 3 | 3.290 | 0.071 | ||

| B250-350 | 3-1/2 | 3.790 | 0.075 | ||

| B250-400 | 4 | 4.290 | 0.078 | ||

| B312-050 | 5/16 | 8 | 1/2 | 0.830 | 0.063 |

| B312-075 | 3/4 | 1.080 | 0.065 | ||

| B312-100 | 1 | 1.330 | 0.068 | ||

| B312-125 | 1-1/4 | 1.580 | 0.071 | ||

| B312-150 | 1-1/2 | 1.830 | 0.074 | ||

| B312-200 | 1-3/4 | 2.330 | 0.080 | ||

| B312-250 | 2 | 2.830 | 0.085 | ||

| B312-300 | 2-1/2 | 3.330 | 0.091 | ||

| B312-350 | 3 | 3.830 | 0.097 | ||

| B312-400 | 3-1/2 | 4.330 | 0.102 | ||

| B312-450 | 4-1/2 | 4.830 | 0.108 | ||

| B312-500 | 5 | 5.330 | 0.114 | ||

| B312-600 | 6 | 6.330 | 0.125 | ||

The main feature of Button Handle Quick Release Pins is their quick-release functionality, which allows for fast and easy securing and releasing of components without the need for additional tools. This is enabled by a button or handle mechanism that locks and unlocks the pin.

The pin has a button or handle that, when pressed or pulled, engages or disengages the locking mechanism, allowing for a quick release.

The quick-release pin can be inserted, locked, and released without the use of any external tools, providing convenience and speed in operations.

Inside the pin, a spring-loaded mechanism (such as a ball or pin) securely locks the pin in place when it is inserted. This ensures the components stay connected until the button is pressed to release it.

The pin is typically made from high-strength materials like stainless steel, offering strength and resistance to wear and corrosion.

In short, the Button Handle Quick Release Pin is designed for fast, secure, and tool-free fastening and unfastening of parts or components.

Button Handle Quick Release Pins have a wide range of applications across various industries due to their ability to provide quick and

secure fastening and releasing of components without the need for tools.

Here are some common applications of Button Handle Quick Release pins:

Aircraft Maintenance: Quick-release pins are used in aviation for securing panels, seats, or structural components that may need to be frequently accessed for maintenance or replacement.

Aircraft Assemblies: They are used to quickly attach or detach parts of aircraft systems or structures during assembly, testing, or modifications.

Vehicle Assembly: In some vehicles, button handle quick release pins are used for attaching parts like bumpers, hoods, or interior panels, making them easier to remove when servicing.

Machine Setup: In settings like CNC machines, 3D printers, or other automated systems, these pins are used to securely hold parts in place during operation but allow quick adjustments or swaps when needed.

Scaffolding: These pins are often used in scaffolding systems to securely attach poles, crossbars, and other components. The quick-release function makes it

easy to dismantle and reassemble scaffolds.Modular Construction: In modular building systems, quick release pins facilitate easy and fast assembly and disassembly of structural components.

Bicycles: In certain bicycles or bike racks, button handle quick-release pins are used to secure wheels, seats, or other components for quick adjustment or removal.

Boating: In boats and marine vessels, quick-release pins are used to secure items like seats, rigging, or transoms, making it easy to adjust or remove parts when necessary.

Contact us now to learn more about the advantages of Button Handle Quick Release Pins and let us drive your productivity improvement together!

SUPPLY MANY KINDS OF BUTTON HANDLE QUICK RELEASE PINS.

WELCOME TO CONSULT US OTHER TYPE, SIZE, MATERIAL AND PRICE.

Made from carbon steel with a zinc finish that resists corrosion, this clevis hitch pin roll pin offers a low-cost option for replacing worn or broken pins on farm implements.

#material:mild steel

#Yellow Zinc Plated or Bright Zinc Plated

A top link is the upper centre arm of a tractor three-point hitch which is used to attach implements to the tractor such as ploughs and hay tines.

#Material:Alloy Steel/mild steel

#Finish Type:Powder Coated

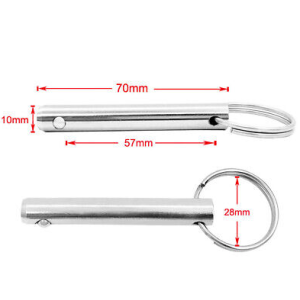

Pull Ring Detent Pins,also known as cotterless hitch pins or quick-release pins,which is a type of fastener commonly used to secure or lock parts in place temporarily. It features a detent mechanism (typically a spring-loaded ball bearing or pin) and a pull ring for easy removal.

# Material: Steel, zinc plated

# Customization Sizes are Available